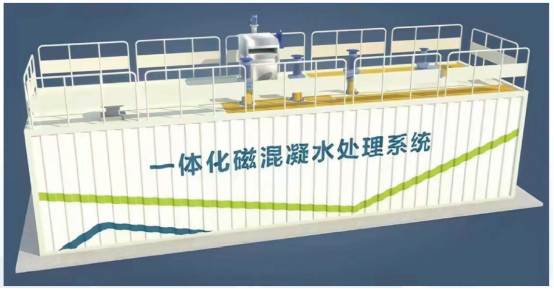

1. Black and Odorous Water Treatment Equipment — Integrated Magnetic Flocculation

(1) Features

* Reduced Turbidity, Synergistic Removal of Multiple Pollutants: The magnetic flocculation process, through the synergistic effect of magnetic particles and flocculants, can simultaneously and efficiently remove suspended solids (SS removal rate > 95%), total phosphorus (TP removal rate > 90%), and colloidal COD (removal rate increased by more than 20%), achieving deep purification of pollutants.

* Ultra-High-Speed Settling Performance: The density of the formed magnetic flocs can reach 2.5-3.0 g/cm³, and the settling speed reaches 40 m/h, which is 20 times that of traditional inclined tube sedimentation, significantly shortening the hydraulic retention time to 7-15 minutes.

* Resistance to Shock Loads: Even when the influent SS concentration fluctuates by 50-500 mg/L, it can still maintain a stable effluent SS < 5 mg/L, making it particularly suitable for treatment scenarios with large fluctuations in raw water quality.

(2) Process Flow

Four-stage reaction system: including a rapid mixing zone (addition of PAC/PAM), a magnetic powder loading zone (addition of Fe₃O₄ magnetic seeds), a flocculation reaction zone (slow stirring to form magnetic flocs), and a sedimentation separation zone (inclined plate sedimentation + magnetic drum recovery). The total hydraulic retention time is only 7-15 minutes.

Magnetic seed circulation system: adopts a rare earth permanent magnet drum recovery device, with a magnetic powder recovery rate ≥99%. The recovered magnetic powder can be reused more than 200 times after activation, reducing the cost per ton of water treatment by 0.1-0.3 yuan.

Chemical dosing system: adjusts the dosage of coagulant (such as polyaluminum chloride) in real time by testing water quality data such as turbidity and pH, reducing the consumption of chemicals.

Magnetic powder recovery system:

High-shear separation device: equipped with a variable frequency high-speed shear machine (speed 3000-5000rpm), which mechanically breaks down the sludge floc structure, releasing the encapsulated magnetic seeds. The recovery rate is as high as 99%, and the magnetic powder loss rate is less than 1%. Magnetic Separator Optimization: Utilizing neodymium iron boron permanent magnets to form a multi-pole magnetic system with a surface magnetic field strength ≥5000Gs, the magnetic drum speed is adjustable (2-10rpm). Combined with high-pressure flushing nozzles, it achieves efficient magnetic powder stripping, recovering magnetic powder with a purity of over 95%.

Sludge Diversion System: A screw conveyor and sludge buffer tank are installed. The separated residual sludge (moisture content ≤98%) is directly discharged into the dewatering equipment, while the magnetic powder is recycled back to the loading reaction tank, reducing operating costs by 30%-40%.

2. Rainwater Purification and Domestic Sewage Upgrading (Integrated Water Purification Device)

(1) Features

The integrated water purification device comprises eight main units: water distribution, reaction, sedimentation, filtration, water collection, sludge collection, and automatic backwashing. It is equipped with PPC inclined tube packing and various specifications of refined filter media. The main shell of the equipment is made of carbon steel, and the interior and exterior are treated with special coatings for corrosion protection. It has the advantages of long service life, wide applicability, and excellent performance, and is widely used in the construction and renovation of large, medium, and small water companies (stations). This device is technologically advanced, novel in design, compact in structure, saves area and investment, is simple to manage, and easy to operate. It treats source water turbidity to less than 3000 mg/L (up to 3000 mg/L in a short time), and effluent turbidity not greater than 3 mg/L. After chlorination disinfection, it meets the national drinking water standards.

(2) Working Principle

The water purification system consists of a coagulation tank, sedimentation tank, filtration tank, water quality stabilization dosing device, backwashing device, water pump, and electrical control cabinet, etc.:

Coagulation Tank: Utilizing a WTH pipeline static mixer, the coagulant is automatically mixed hydraulically. Raw water with added coagulant enters the coagulation tank through the inlet pipe, where it mixes with the coagulant using a specially designed vortex reaction, ensuring sufficient contact and reaction between suspended solids and the coagulant to form flocs. The effect is unaffected by changes in water volume.

Sedimentation Tank: After coagulation with coagulant, the water forms flocs, which flow into the sedimentation tank for settling. The sedimentation tank uses inclined tube sedimentation with a surface loading of 7-8 m³/(m²·h). Filtration Tank: After sedimentation, the water flows into the filtration tank for further filtration. The tank structure consists of a bottom distribution pipe and a middle and upper section filled with quartz sand. The filtration rate is 7-10 m/h, and the backwash intensity is 14-16 liters/(m²·s). Finally, the clear water flows into a clear water tank for disinfection before drinking. The backwash cycle of the filtration tank is approximately 12 hours, with a backwash time of 5-10 minutes. The filtration section uses quartz sand.